426

14 CFR Ch. I (1–1–19 Edition)

Pt. 25, App. F

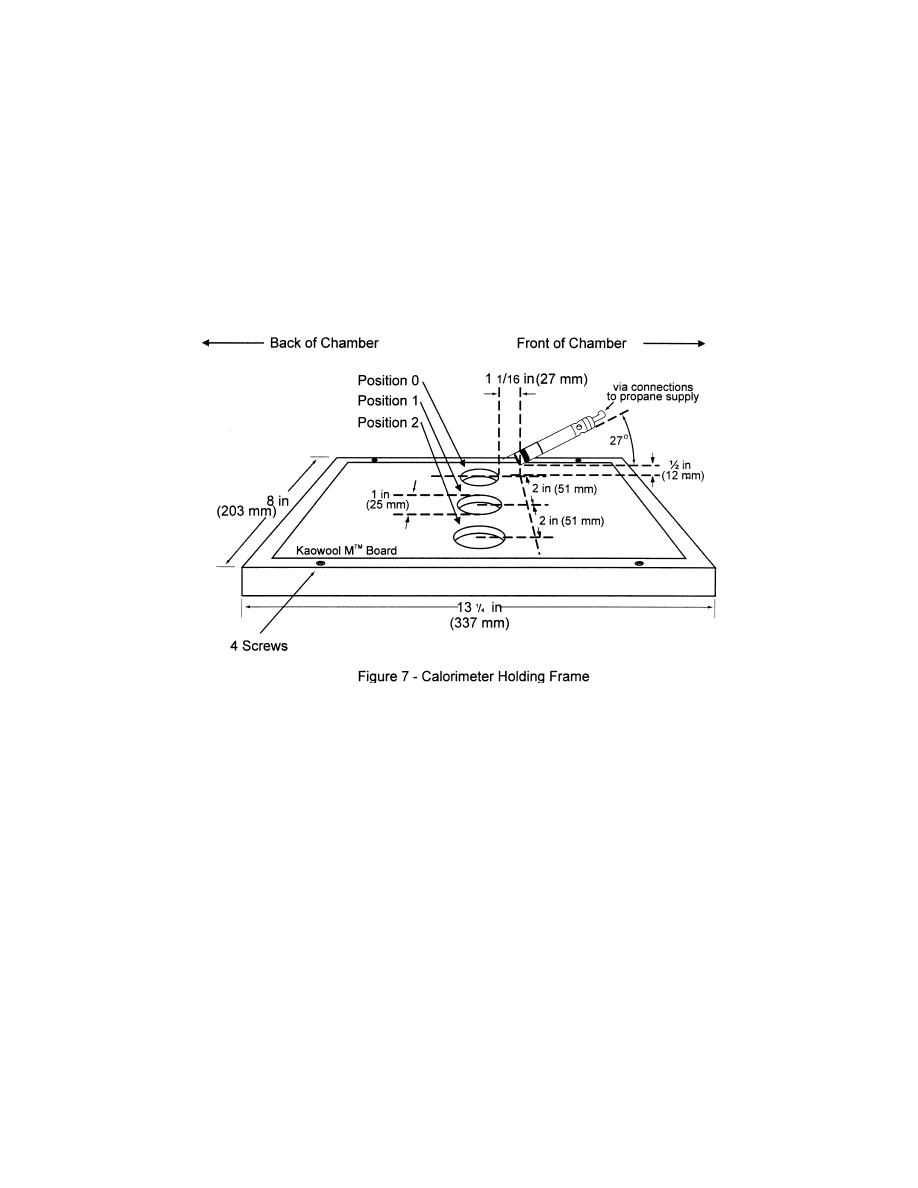

first hole to the radiant panel and the dis-

tance between holes is the same as described

in this paragraph.

(9)

Instrumentation.

Provide a calibrated re-

cording device with an appropriate range or

a computerized data acquisition system to

measure and record the outputs of the calo-

rimeter and the thermocouple. The data ac-

quisition system must be capable of record-

ing the calorimeter output every second dur-

ing calibration.

(10)

Timing device.

Provide a stopwatch or

other device, accurate to

±

1 second/hour, to

measure the time of application of the pilot

burner flame.

(c)

Test specimens.

(1)

Specimen preparation.

Prepare and test a minimum of three test

specimens. If an oriented film cover material

is used, prepare and test both the warp and

fill directions.

(2)

Construction.

Test specimens must in-

clude all materials used in construction of

the insulation (including batting, film,

scrim, tape etc.). Cut a piece of core material

such as foam or fiberglass, and cut a piece of

film cover material (if used) large enough to

cover the core material. Heat sealing is the

preferred method of preparing fiberglass

samples, since they can be made without

compressing the fiberglass (‘‘box sample’’).

Cover materials that are not heat sealable

may be stapled, sewn, or taped as long as the

cover material is over-cut enough to be

drawn down the sides without compressing

the core material. The fastening means

should be as continuous as possible along the

length of the seams. The specimen thickness

must be of the same thickness as installed in

the airplane.

(3)

Specimen Dimensions.

To facilitate prop-

er placement of specimens in the sliding

platform housing, cut non-rigid core mate-

rials, such as fiberglass, 12

1

⁄

2

inches (318mm)

wide by 23 inches (584mm) long. Cut rigid

materials, such as foam, 11

1

⁄

2

±

1

⁄

4

inches (292

mm

±

6mm) wide by 23 inches (584mm) long in

order to fit properly in the sliding platform

housing and provide a flat, exposed surface

equal to the opening in the housing.

(d)

Specimen conditioning.

Condition the

test specimens at 70

±

5

°

F (21

±

2

°

C) and 55%

±

10% relative humidity, for a minimum of 24

hours prior to testing.

(e)

Apparatus Calibration.

(1) With the slid-

ing platform out of the chamber, install the

calorimeter holding frame. Push the plat-

form back into the chamber and insert the

calorimeter into the first hole (‘‘zero’’ posi-

tion).

See

figure 7. Close the bottom door lo-

cated below the sliding platform. The dis-

tance from the centerline of the calorimeter

VerDate Sep<11>2014

12:50 Apr 30, 2019

Jkt 247046

PO 00000

Frm 00436

Fmt 8010

Sfmt 8002

Y:\SGML\247046.XXX

247046

ER31JY03.010</GPH>

spaschal on DSK3GDR082PROD with CFR