254

14 CFR Ch. I (1–1–19 Edition)

§ 25.511

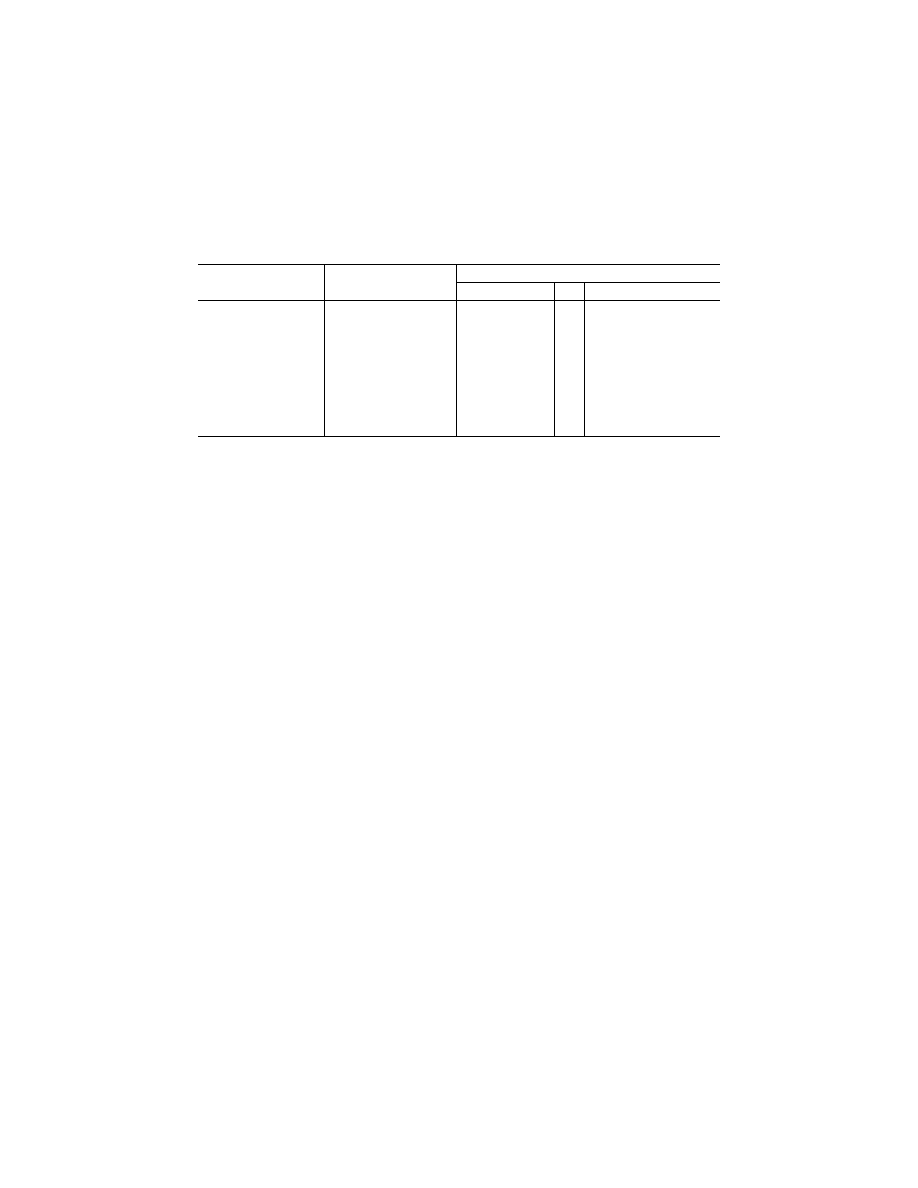

Tow point

Position

Load

Magnitude No.

Direction

Main gear ...............................

................................................

0.75

F

TOW

per main

gear unit.

1

2

3

4

Forward, parallel to drag axis.

Forward, at 30

°

to drag axis.

Aft, parallel to drag axis.

Aft, at 30

°

to drag axis.

Auxiliary gear .........................

Swiveled forward ....................

1.0

F

TOW

...................

5

6

Forward.

Aft.

Swiveled aft ............................

......do .......................

7

8

Forward.

Aft.

Swiveled 45

°

from forward .....

0.5

F

TOW

...................

9

10

Forward, in plane of wheel.

Aft, in plane of wheel.

Swiveled 45

°

from aft .............

......do .......................

11

12

Forward, in plane of wheel.

Aft, in plane of wheel.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25–23, 35 FR 5673, Apr. 8, 1970]

§ 25.511

Ground load: unsymmetrical

loads on multiple-wheel units.

(a)

General.

Multiple-wheel landing

gear units are assumed to be subjected

to the limit ground loads prescribed in

this subpart under paragraphs (b)

through (f) of this section. In addi-

tion—

(1) A tandem strut gear arrangement

is a multiple-wheel unit; and

(2) In determining the total load on a

gear unit with respect to the provisions

of paragraphs (b) through (f) of this

section, the transverse shift in the load

centroid, due to unsymmetrical load

distribution on the wheels, may be ne-

glected.

(b)

Distribution of limit loads to wheels;

tires inflated.

The distribution of the

limit loads among the wheels of the

landing gear must be established for

each landing, taxiing, and ground han-

dling condition, taking into account

the effects of the following factors:

(1) The number of wheels and their

physical arrangements. For truck type

landing gear units, the effects of any

seesaw motion of the truck during the

landing impact must be considered in

determining the maximum design loads

for the fore and aft wheel pairs.

(2) Any differentials in tire diameters

resulting from a combination of manu-

facturing tolerances, tire growth, and

tire wear. A maximum tire-diameter

differential equal to

2

⁄

3

of the most un-

favorable combination of diameter

variations that is obtained when tak-

ing into account manufacturing toler-

ances, tire growth, and tire wear, may

be assumed.

(3) Any unequal tire inflation pres-

sure, assuming the maximum variation

to be

±

5 percent of the nominal tire in-

flation pressure.

(4) A runway crown of zero and a run-

way crown having a convex upward

shape that may be approximated by a

slope of 1

1

⁄

2

percent with the hori-

zontal. Runway crown effects must be

considered with the nose gear unit on

either slope of the crown.

(5) The airplane attitude.

(6) Any structural deflections.

(c)

Deflated tires.

The effect of de-

flated tires on the structure must be

considered with respect to the loading

conditions specified in paragraphs (d)

through (f) of this section, taking into

account the physical arrangement of

the gear components. In addition—

(1) The deflation of any one tire for

each multiple wheel landing gear unit,

and the deflation of any two critical

tires for each landing gear unit using

four or more wheels per unit, must be

considered; and

(2) The ground reactions must be ap-

plied to the wheels with inflated tires

except that, for multiple-wheel gear

units with more than one shock strut,

a rational distribution of the ground

reactions between the deflated and in-

flated tires, accounting for the dif-

ferences in shock strut extensions re-

sulting from a deflated tire, may be

used.

(d)

Landing conditions.

For one and

for two deflated tires, the applied load

to each gear unit is assumed to be 60

percent and 50 percent, respectively, of

the limit load applied to each gear for

VerDate Sep<11>2014

12:50 Apr 30, 2019

Jkt 247046

PO 00000

Frm 00264

Fmt 8010

Sfmt 8010

Y:\SGML\247046.XXX

247046

spaschal on DSK3GDR082PROD with CFR