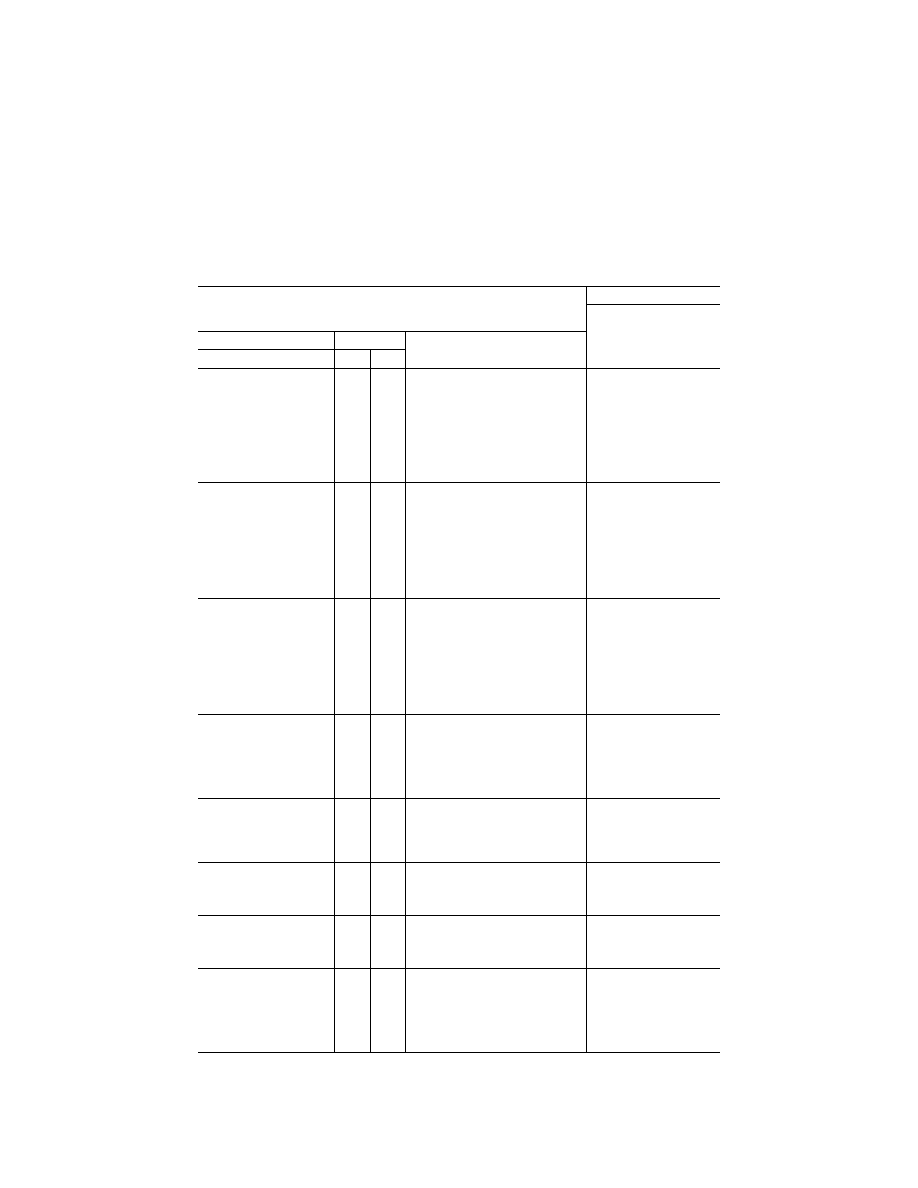

125

Federal Aviation Administration, DOT

Pt. 60, App. A

T

ABLE

A2E—A

LTERNATIVE

D

ATA

S

OURCES

, P

ROCEDURES

,

AND

I

NSTRUMENTATION

—Continued

QPS REQUIREMENTS

The standards in this table are required if the data gathering methods described in paragraph

9 of

Appendix A are not used.

Information

Table of objective tests

Sim level

Alternative data sources, procedures, and

instrumentation

Notes

Test entry number and title

A

B

2.a.1.a. Handling Qualities. Stat-

ic Control Checks. Pitch Con-

troller Position vs. Force and

Surface Position Calibration.

X

X

Surface position data may be acquired

from flight data recorder (FDR) sensor

or, if no FDR sensor, at selected, sig-

nificant column positions (encom-

passing significant column position data

points), acceptable to the NSPM, using

a control surface protractor on the

ground. Force data may be acquired by

using a hand held force gauge at the

same column position data points.

For airplanes with reversible

control systems, surface po-

sition data acquisition should

be accomplished with winds

less than 5 kts.

2.a.2.a. Handling Qualities. Stat-

ic Control Checks. Roll Con-

troller Position vs. Force and

Surface Position Calibration.

X

X

Surface position data may be acquired

from flight data recorder (FDR) sensor

or, if no FDR sensor, at selected, sig-

nificant wheel positions (encompassing

significant wheel position data points),

acceptable to the NSPM, using a con-

trol surface protractor on the ground.

Force data may be acquired by using a

hand held force gauge at the same

wheel position data points.

For airplanes with reversible

control systems, surface po-

sition data acquisition should

be accomplished with winds

less than 5 kts.

2.a.3.a. Handling Qualities. Stat-

ic Control Checks. Rudder

Pedal Position vs. Force and

Surface Position Calibration.

X

X

Surface position data may be acquired

from flight data recorder (FDR) sensor

or, if no FDR sensor, at selected, sig-

nificant rudder pedal positions (encom-

passing significant rudder pedal position

data points), acceptable to the NSPM,

using a control surface protractor on the

ground. Force data may be acquired by

using a hand held force gauge at the

same rudder pedal position data points.

For airplanes with reversible

control systems, surface po-

sition data acquisition should

be accomplished with winds

less than 5 kts.

2.a.4. Handling Qualities. Static

Control Checks. Nosewheel

Steering Controller Force and

Position.

X

X

Breakout data may be acquired with a

hand held force gauge. The remainder

of the force to the stops may be cal-

culated if the force gauge and a pro-

tractor are used to measure force after

breakout for at least 25% of the total

displacement capability.

2.a.5. Handling Qualities. Static

Control Checks. Rudder

Pedal Steering Calibration.

X

X

Data may be acquired through the use of

force pads on the rudder pedals and a

pedal position measurement device, to-

gether with design data for nosewheel

position.

2.a.6. Handling Qualities. Static

Control Checks. Pitch Trim In-

dicator vs. Surface Position

Calibration.

X

X

Data may be acquired through calcula-

tions.

2.a.7. Handling qualities. Static

control tests. Pitch trim rate.

X

X

Data may be acquired by using a syn-

chronized video of pitch trim indication

and elapsed time through range of trim

indication.

2.a.8. Handling Qualities. Static

Control tests. Alignment of

Flight deck Throttle Lever

Angle vs. Selected engine pa-

rameter.

X

X

Data may be acquired through the use of

a temporary throttle quadrant scale to

document throttle position. Use a syn-

chronized video to record steady state

instrument readings or hand-record

steady state engine performance read-

ings.

VerDate Sep<11>2014

16:30 Jun 25, 2019

Jkt 247047

PO 00000

Frm 00135

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

kpayne on VMOFRWIN702 with $$_JOB