282

14 CFR Ch. I (1–1–19 Edition)

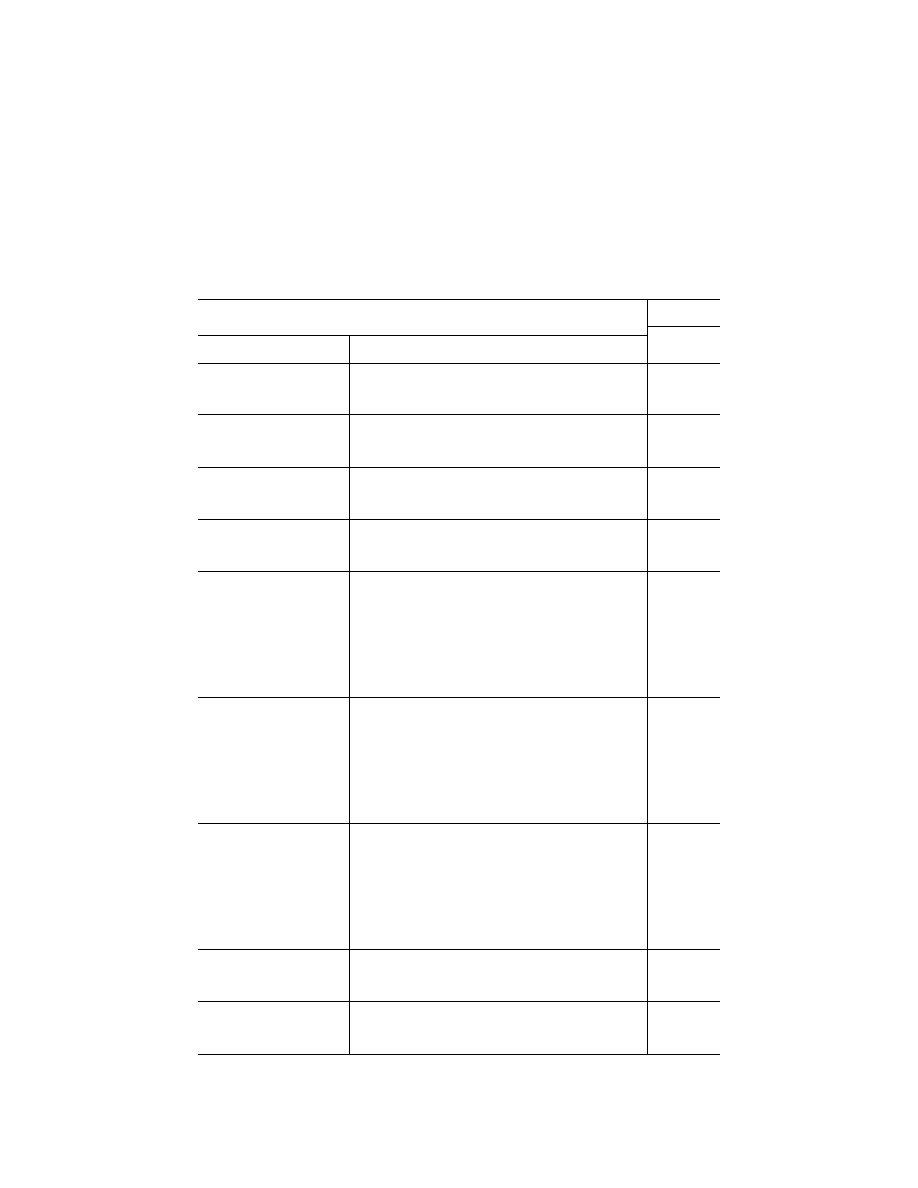

Pt. 60, App. B

T

ABLE

B2F—A

LTERNATIVE

D

ATA

S

OURCES

, P

ROCEDURES

,

AND

I

NSTRUMENTATION

L

EVEL

6 FTD—

Continued

QPS Requirements

The standards in this table are required if the data gathering methods described in paragraph 9 of Appendix

B are not used.

Information

Objective test reference number

and title

Alternative data sources, procedures, and instrumentation

Notes

1.b.7. ................................................

Performance.

Takeoff.

Rejected takeoff.

Data may be acquired through a synchronized video recording of a

stop watch and the calibrated airplane airspeed indicator. Hand-

record the flight conditions and airplane configuration.

This test is re-

quired only if

RTO is

sought.

1.c.1. ................................................

Performance.

Climb.

Normal climb all engines operating.

Data may be acquired with a synchronized video of calibrated airplane

instruments and engine power throughout the climb range.

1.f.1. .................................................

Performance.

Engines.

Acceleration

Data may be acquired with a synchronized video recording of engine

instruments and throttle position.

1.f.2. .................................................

Performance.

Engines.

Deceleration

Data may be acquired with a synchronized video recording of engine

instruments and throttle position.

2.a.1.a. .............................................

Handling qualities.

Static control tests.

Pitch controller position vs. force

and surface position calibration.

Surface position data may be acquired from flight data recorder (FDR)

sensor or, if no FDR sensor, at selected, significant column positions

(encompassing significant column position data points), acceptable

to the NSPM, using a control surface protractor on the ground. Force

data may be acquired by using a hand held force gauge at the same

column position data points.

For airplanes

with reversible

control sys-

tems, surface

position data

acquisition

should be ac-

complished

with winds

less than 5

kts.

2.a.2.a. .............................................

Handling qualities.

Static control tests.

Wheel position vs. force and sur-

face position calibration.

Surface position data may be acquired from flight data recorder (FDR)

sensor or, if no FDR sensor, at selected, significant wheel positions

(encompassing significant wheel position data points), acceptable to

the NSPM, using a control surface protractor on the ground. Force

data may be acquired by using a hand held force gauge at the same

wheel position data points.

For airplanes

with reversible

control sys-

tems, surface

position data

acquisition

should be ac-

complished

with winds

less than 5

kts.

2.a.3.a. .............................................

Handling qualities.

Static control tests.

Rudder pedal position vs. force and

surface position calibration.

Surface position data may be acquired from flight data recorder (FDR)

sensor or, if no FDR sensor, at selected, significant rudder pedal po-

sitions (encompassing significant rudder pedal position data points),

acceptable to the NSPM, using a control surface protractor on the

ground. Force data may be acquired by using a hand held force

gauge at the same rudder pedal position data points.

For airplanes

with reversible

control sys-

tems, surface

position data

acquisition

should be ac-

complished

with winds

less than 5

kts.

2.a.4. ................................................

Handling qualities.

Static control tests.

Nosewheel steering force.

Breakout data may be acquired with a hand held force gauge. The re-

mainder of the force to the stops may be calculated if the force

gauge and a protractor are used to measure force after breakout for

at least 25% of the total displacement capability.

2.a.5. ................................................

Handling qualities.

Static control tests.

Rudder pedal steering calibration.

Data may be acquired through the use of force pads on the rudder

pedals and a pedal position measurement device, together with de-

sign data for nosewheel position.

VerDate Sep<11>2014

16:30 Jun 25, 2019

Jkt 247047

PO 00000

Frm 00292

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

kpayne on VMOFRWIN702 with $$_JOB