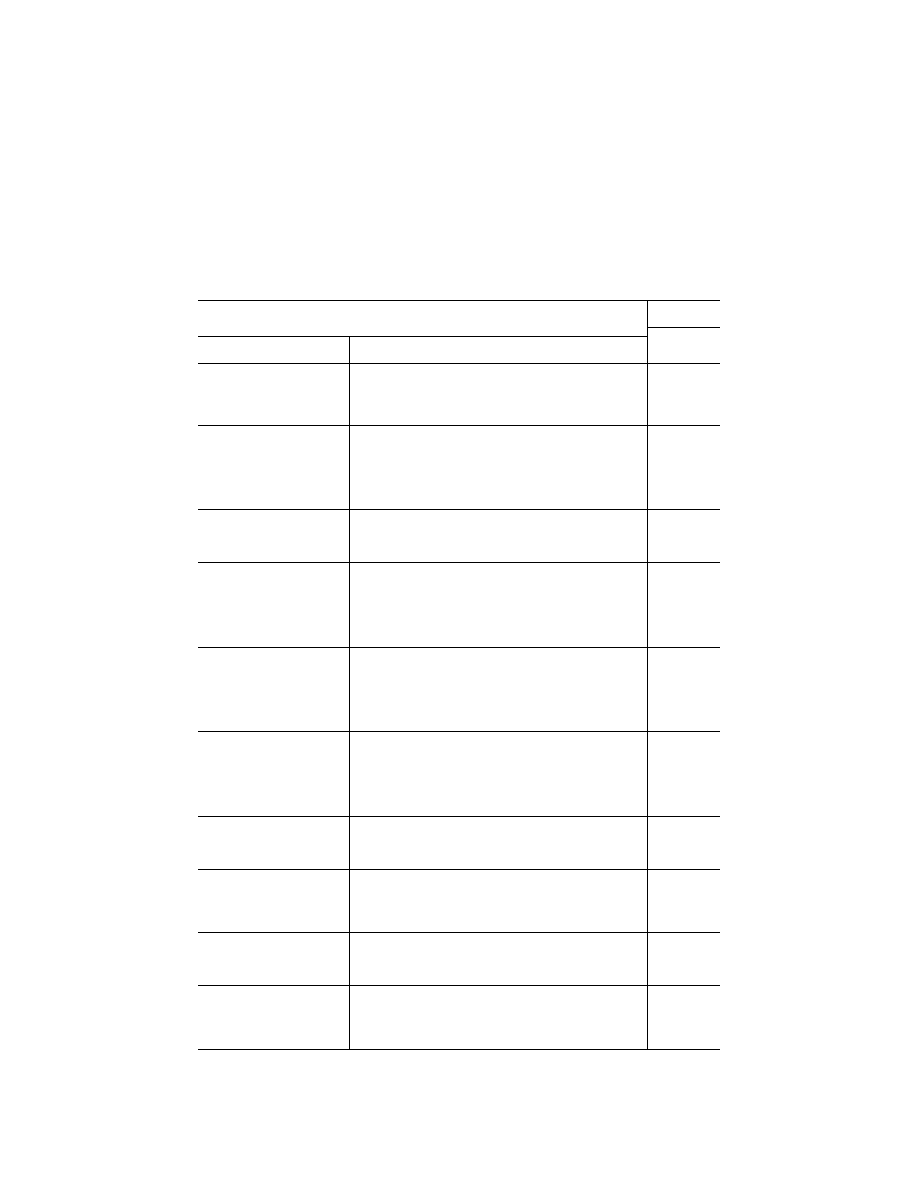

283

Federal Aviation Administration, DOT

Pt. 60, App. B

T

ABLE

B2F—A

LTERNATIVE

D

ATA

S

OURCES

, P

ROCEDURES

,

AND

I

NSTRUMENTATION

L

EVEL

6 FTD—

Continued

QPS Requirements

The standards in this table are required if the data gathering methods described in paragraph 9 of Appendix

B are not used.

Information

Objective test reference number

and title

Alternative data sources, procedures, and instrumentation

Notes

2.a.6. ................................................

Handling qualities.

Static control tests.

Pitch trim indicator vs. surface posi-

tion calibration.

Data may be acquired through calculations.

2.a.8. ................................................

Handling qualities.

Static control tests.

Alignment of power lever angle vs.

selected engine parameter (e.g.,

EPR, N

1

, Torque, Manifold pres-

sure).

Data may be acquired through the use of a temporary throttle quadrant

scale to document throttle position. Use a synchronized video to

record steady state instrument readings or hand-record steady state

engine performance readings.

2.a.9. ................................................

Handling qualities.

Static control tests.

Brake pedal position vs. force.

Use of design or predicted data is acceptable. Data may be acquired

by measuring deflection at ‘‘zero’’ and at ‘‘maximum.’’

2.c.1. ................................................

Handling qualities.

Longitudinal control tests.

Power change force.

Data may be acquired by using an inertial measurement system and a

synchronized video of the calibrated airplane instruments, throttle po-

sition, and the force/position measurements of flight deck controls.

Power change

dynamics test

is acceptable

using the

same data ac-

quisition

methodology.

2.c.2. ................................................

Handling qualities.

Longitudinal control tests.

Flap/slat change force.

Data may be acquired by using an inertial measurement system and a

synchronized video of calibrated airplane instruments, flap/slat posi-

tion, and the force/position measurements of flight deck controls.

Flap/slat change

dynamics test

is acceptable

using the

same data ac-

quisition

methodology.

2.c.4. ................................................

Handling qualities.

Longitudinal control tests.

Gear change force.

Data may be acquired by using an inertial measurement system and a

synchronized video of the calibrated airplane instruments, gear posi-

tion, and the force/position measurements of flight deck controls.

Gear change dy-

namics test is

acceptable

using the

same data ac-

quisition

methodology.

2.c.5. ................................................

Handling qualities.

Longitudinal control tests.

Longitudinal trim.

Data may be acquired through use of an inertial measurement system

and a synchronized video of flight deck controls position (previously

calibrated to show related surface position) and engine instrument

readings.

2.c.6. ................................................

Handling qualities.

Longitudinal control tests.

Longitudinal maneuvering stability

(stick force/g).

Data may be acquired through the use of an inertial measurement sys-

tem and a synchronized video of the calibrated airplane instruments;

a temporary, high resolution bank angle scale affixed to the attitude

indicator; and a wheel and column force measurement indication.

2.c.7. ................................................

Handling qualities.

Longitudinal control tests.

Longitudinal static stability

Data may be acquired through the use of a synchronized video of the

airplane flight instruments and a hand held force gauge.

2.c.8. ................................................

Handling qualities.

Longitudinal control tests.

Stall Warning (activation of stall

warning device).

Data may be acquired through a synchronized video recording of a

stop watch and the calibrated airplane airspeed indicator. Hand-

record the flight conditions and airplane configuration.

Airspeeds may

be cross

checked with

those in the

TIR and AFM.

VerDate Sep<11>2014

16:30 Jun 25, 2019

Jkt 247047

PO 00000

Frm 00293

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

kpayne on VMOFRWIN702 with $$_JOB