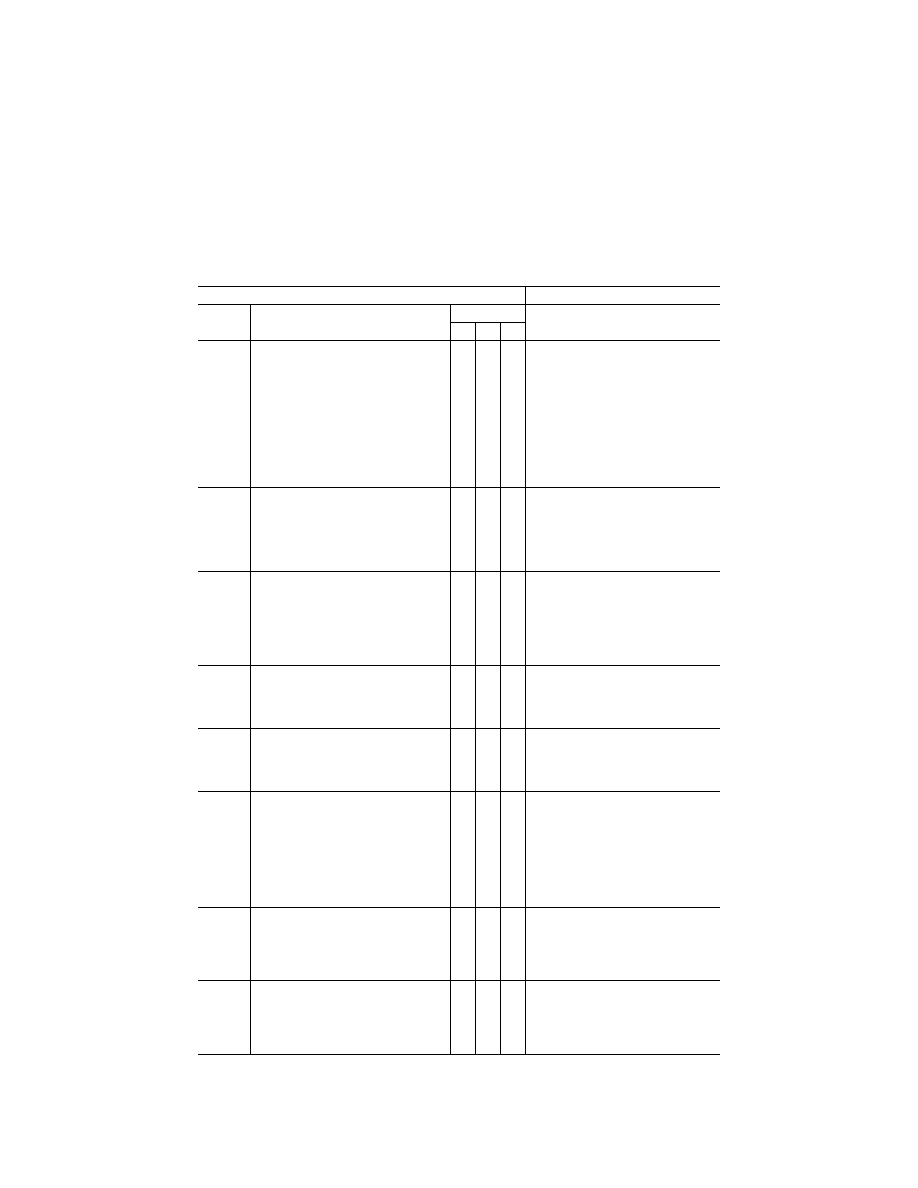

402

14 CFR Ch. I (1–1–19 Edition)

Pt. 60, App. C

T

ABLE

C3D—F

UNCTIONS AND

S

UBJECTIVE

T

ESTS

—Continued

QPS requirements

Information

Entry No.

Motion system (and special

aerodynamic model) effects

Simulator level

Notes

B C D

1 ...............

Runway rumble, oleo deflection, ground

speed, uneven runway, runway and taxi-

way centerline light characteristics:

Procedure: After the helicopter has been pre-

set to the takeoff position and then released,

taxi at various speeds with a smooth runway

and note the general characteristics of the

simulated runway rumble effects of oleo de-

flections. Repeat the maneuver with a run-

way roughness of 50%, then with maximum

roughness. Note the associated motion vi-

brations affected by ground speed and run-

way roughness

X

X

X If time permits, different gross weights can

also be selected as this may also affect the

associated vibrations depending on heli-

copter type. The associated motion effects

for the above tests should also include an

assessment of the effects of rolling over

centerline lights, surface discontinuities of

uneven runways, and various taxiway char-

acteristics.

2 ...............

Friction Drag from Skid-type Landing Gear:

Procedure: Perform a running takeoff or a run-

ning landing and note an increase in a fuse-

lage vibration (as opposed to rotor vibration)

due to the friction of dragging the skid along

the surface. This vibration will lessen as the

ground speed decreases

X X

3. ..............

Rotor Out-of-Track and/or Out-of-Balance

condition:

Procedure: Select the malfunction or condition

from the IOS. Start the engine(s) normally

and check for an abnormal vibration for an

Out-of-Track condition and check for an ab-

normal vibration for an Out-of-Balance con-

dition

X

X

X

Does not require becoming airborne. The ab-

normal vibration for Out-of-Track and Out-of-

Balance conditions should be recognized in

the frequency range of the inverse of the

period for each; i.e., 1/P for vertical vibra-

tion, and 1/P for lateral vibration.

4. ..............

Bumps associated with the landing gear:

Procedure: Perform a normal take-off paying

special attention to the bumps that could be

perceptible due to maximum oleo extension

after lift-off

X

X

X When the landing gear is extended or re-

tracted, motion bumps can be felt when the

gear locks into position.

5. ..............

Buffet during extension and retraction of

landing gear:

Procedure: Operate the landing gear. Check

that the motion cues of the buffet experi-

enced represent the actual helicopter

X X X

6. ..............

Failure of Dynamic Vibration Absorber or

similar system as appropriate for the hel-

icopter (e.g., droop stop or static stop):

Procedure: May be accomplished any time the

rotor is engaged. Select the appropriate fail-

ure at the IOS, note an appropriate increase

in vibration and check that the vibration in-

tensity and frequency increases with an in-

crease in RPM and an increase in collective

application

X X X

7. ..............

Tail Rotor Drive Failure:

Procedure: With the engine(s) running and the

rotor engaged—select the malfunction and

note the immediate increase of medium fre-

quency vibration

X

X

X The tail rotor operates in the medium fre-

quency range, normally estimated by multi-

plying the tail rotor gear box ratio by the

main rotor RPM. The failure can be recog-

nized by an increase in the vibrations in this

frequency range.

8. ..............

Touchdown cues for main and nose gear:

Procedure: Conduct several normal ap-

proaches with various rates of descent.

Check that the motion cues for the touch-

down bumps for each descent rate are rep-

resentative of the actual helicopter

X X X

VerDate Sep<11>2014

16:30 Jun 25, 2019

Jkt 247047

PO 00000

Frm 00412

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

PC31

kpayne on VMOFRWIN702 with $$_JOB