363

Pipeline and Haz. Matls. Safety Admin., DOT

§ 172.102

hour per square meter per degree Celsius

(0.075 Btu per hour per square foot per de-

gree Fahrenheit) temperature differential.

Insulating materials must not promote

corrosion to steel when wet.

B15

Packagings must be protected with

non-metallic linings impervious to the lad-

ing or have a suitable corrosion allowance.

B16

The lading must be completely covered

with nitrogen, inert gas or other inert ma-

terials.

B18

Open steel hoppers or bins are author-

ized.

B23

Tanks must be made of steel that is

rubber lined or unlined. Unlined tanks

must be passivated before being placed in

service. If unlined tanks are washed out

with water, they must be repassivated

prior to return to service. Lading in un-

lined tanks must be inhibited so that the

corrosive effect on steel is not greater than

that of hydrofluoric acid of 65 percent con-

centration.

B25

Packagings must be made from monel

or nickel or monel-lined or nickel-lined

steel.

B26

Tanks must be insulated. Insulation

must be at least 100 mm (3.9 inches) except

that the insulation thickness may be re-

duced to 51 mm (2 inches) over the exterior

heater coils. Interior heating coils are not

authorized. The packaging may not be

loaded with a material outside of the pack-

aging’s design temperature range. In addi-

tion, the material also must be covered

with an inert gas or the container must be

filled with water to the tank’s capacity.

After unloading, the residual material also

must be covered with an inert gas or the

container must be filled with water to the

tank’s capacity.

B27

Tanks must have a service pressure of

1,034 kPa (150 psig). Tank car tanks must

have a test pressure rating of 1,379 kPa (200

psig). Lading must be blanketed at all

times with a dry inert gas at a pressure not

to exceed 103 kPa (15 psig).

B28

Packagings must be made of stainless

steel.

B30

MC 312, MC 330, MC 331 and DOT 412

cargo tanks and DOT 51 portable tanks

must be made of stainless steel, except

that steel other than stainless steel may

be used in accordance with the provisions

of § 173.24b(b) of this subchapter. Thickness

of stainless steel for tank shell and heads

for cargo tanks and portable tanks must be

the greater of 7.62 mm (0.300 inch) or the

thickness required for a tank with a design

pressure at least equal to 1.5 times the

vapor pressure of the lading at 46

°

C (115

°

F). In addition, MC 312 and DOT 412 cargo

tank motor vehicles must:

a. Be ASME Code (U) stamped for 100% ra-

diography of all pressure-retaining welds;

b. Have accident damage protection which

conforms with § 178.345–8 of this sub-

chapter;

c. Have a MAWP or design pressure of at

least 87 psig: and

d. Have a bolted manway cover.

B32

MC 312, MC 330, MC 331, DOT 412 cargo

tanks and DOT 51 portable tanks must be

made of stainless steel, except that steel

other than stainless steel may be used in

accordance with the provisions of

§ 173.24b(b) of this subchapter. Thickness of

stainless steel for tank shell and heads for

cargo tanks and portable tanks must be

the greater of 6.35 mm (0.250 inch) or the

thickness required for a tank with a design

pressure at least equal to 1.3 times the

vapor pressure of the lading at 46

°

C (115

°

F). In addition, MC 312 and DOT 412 cargo

tank motor vehicles must:

a. Be ASME Code (U) stamped for 100% radi-

ography of all pressure-retaining welds;

b. Have accident damage protection which

conforms with § 178.345–8 of this sub-

chapter;

c. Have a MAWP or design pressure of at

least 87 psig; and

d. Have a bolted manway cover.

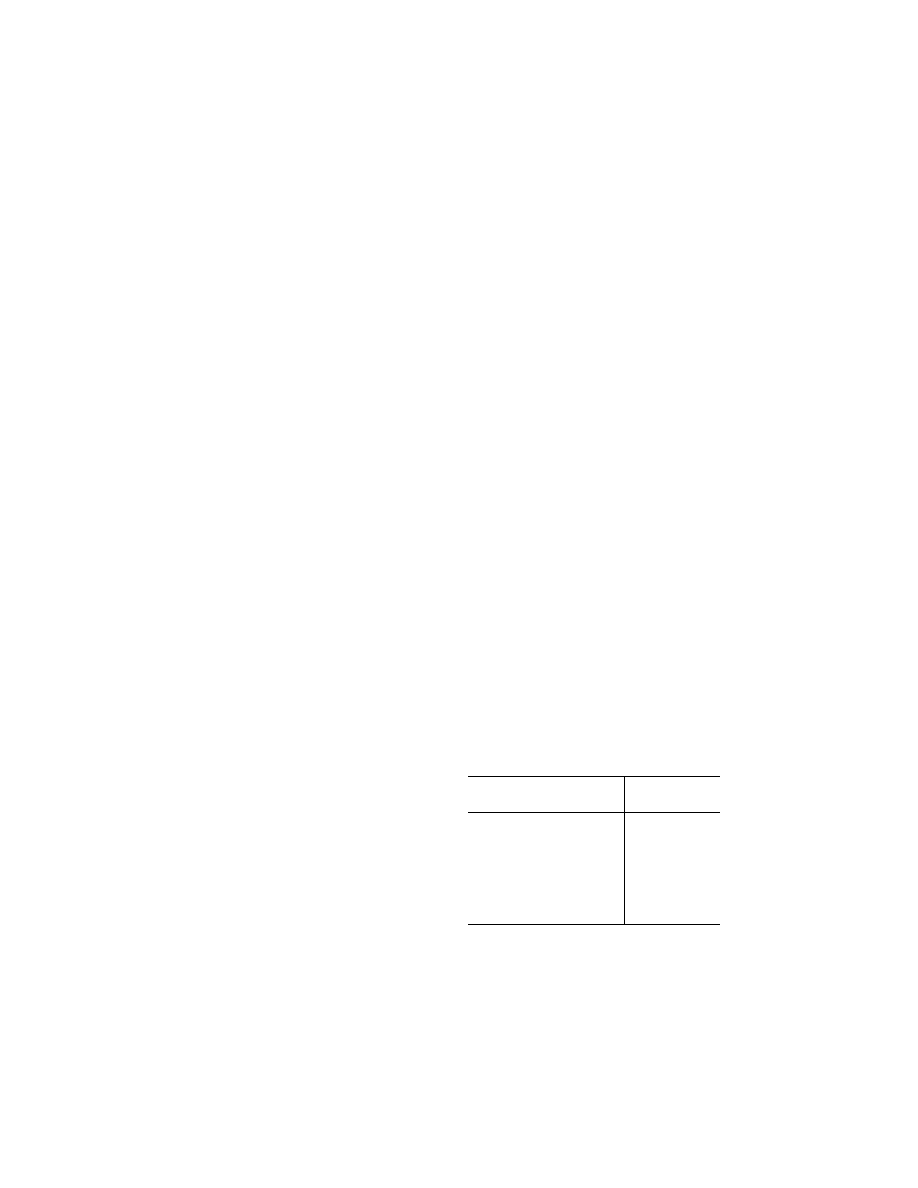

B33

MC 300, MC 301, MC 302, MC 303, MC 305,

MC 306, and DOT 406 cargo tanks equipped

with a 1 psig normal vent used to transport

gasoline must conform to Table I of this

Special Provision. Based on the volatility

class determined by using ASTM D 439 and

the Reid vapor pressure (RVP) of the par-

ticular gasoline, the maximum lading pres-

sure and maximum ambient temperature

permitted during the loading of gasoline

may not exceed that listed in Table I.

T

ABLE

I—M

AXIMUM

A

MBIENT

T

EMPERATURE

—

G

ASOLINE

ASTM D439 volatility class

Maximum lading and

ambient temperature

(see note 1)

A ........................................................

131

°

F

(RVP

≤

9.0 psia)

B ........................................................

124

°

F

(RVP

≤

10.0 psia)

C ........................................................

116

°

F

(RVP

≤

11.5 psia)

D ........................................................

107

°

F

(RVP

≤

13.5 psia)

E ........................................................

100

°

F

(RVP

≤

15.0 psia)

N

OTE

1: Based on maximum lading pressure of 1 psig at

top of cargo tank.

B35

Tank cars containing hydrogen cyanide

may be alternatively marked

‘‘Hydrocyanic acid, liquefied’’ if otherwise

conforming to marking requirements in

subpart D of this part. Tank cars marked

‘‘HYDROCYANIC ACID’’ prior to October

1, 1991 do not need to be remarked.

B42

Tank cars constructed before March 16,

2009, must have a test pressure of 34.47 Bar

VerDate Sep<11>2014

16:41 Oct 31, 2018

Jkt 244226

PO 00000

Frm 00373

Fmt 8010

Sfmt 8010

Q:\49\49V2.TXT

PC31