367

Pipeline and Haz. Matls. Safety Admin., DOT

§ 172.102

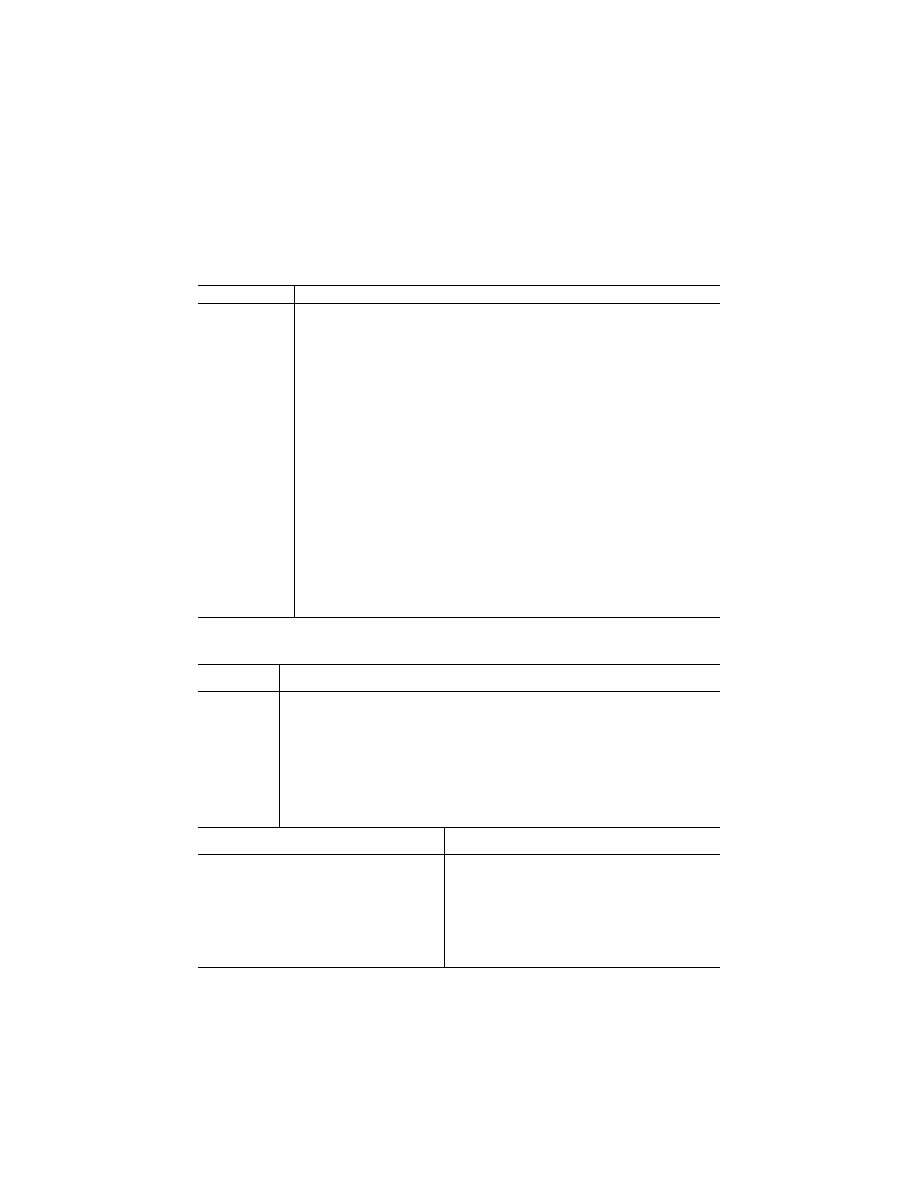

T

ABLE

2—IP C

ODES

IP code

IP1 .............................

IBCs must be packed in closed freight containers or a closed transport vehicle.

IP2 .............................

When IBCs other than metal or rigid plastics IBCs are used, they must be offered for transportation in a

closed freight container or a closed transport vehicle.

IP3 .............................

Flexible IBCs must be sift-proof and water-resistant or must be fitted with a sift-proof and water-resist-

ant liner.

IP4 .............................

Flexible, fiberboard or wooden IBCs must be sift-proof and water-resistant or be fitted with a sift-proof

and water-resistant liner.

IP5 .............................

IBCs must have a device to allow venting. The inlet to the venting device must be located in the vapor

space of the IBC under maximum filling conditions.

IP6 .............................

Non-specification bulk bins are authorized.

IP7 .............................

For UN identification numbers 1327, 1363, 1364, 1365, 1386, 1841, 2211, 2217, 2793 and 3314, IBCs

are not required to meet the IBC performance tests specified in part 178, subpart N, of this sub-

chapter.

IP8 .............................

Ammonia solutions may be transported in rigid or composite plastic IBCs (31H1, 31H2 and 31HZ1) that

have successfully passed, without leakage or permanent deformation, the hydrostatic test specified in

§ 178.814 of this subchapter at a test pressure that is not less than 1.5 times the vapor pressure of

the contents at 55

°

C (131

°

F).

IP13 ...........................

Transportation by vessel in IBCs is prohibited.

IP14 ...........................

Air must be eliminated from the vapor space by nitrogen or other means.

IP15 ...........................

For UN2031 with more than 55% nitric acid, rigid plastic IBCs and composite IBCs with a rigid plastic

inner receptacle are authorized for two years from the date of IBC manufacture.

IP16 ...........................

IBCs of type 31A and 31N are only authorized if approved by the Associate Administrator.

IP19 ...........................

For UN identification numbers 3531, 3532, 3533, and 3534, IBCs must be designed and constructed to

permit the release of gas or vapor to prevent a build-up of pressure that could rupture the IBCs in the

event of loss of stabilization.

IP20 ...........................

Dry sodium cyanide or potassium cyanide is also permitted in siftproof, water-resistant, fiberboard IBCs

when transported in closed freight containers or transport vehicles.

IP21 ...........................

When transported by vessel, flexible, fiberboard or wooden IBCs must be sift-proof and water-resistant

or be fitted with a sift-proof and water-resistant liner.

T

ABLE

3—IB C

ODES

[Large packaging authorizations]

IB3

Authorized Large Packagings (LIQUIDS)

(PG III materials only)

2

Inner packagings:

Large outer packagings:

Glass

10

liter.

steel (50A).

Plastics

30

liter.

aluminum (50B).

Metal

40

liter.

metal other than steel or aluminum (50N).

rigid plastics (50H).

natural wood (50C).

plywood (50D).

reconstituted wood (50F).

rigid fiberboard (50G).

IB8

Authorized Large Packagings (SOLIDS)

(PG III materials only)

2

Inner packagings:

Large outer packagings:

Glass

10 kg ...........................................................

steel (50A).

Plastics

50 kg .......................................................

aluminum (50B).

Metal

50 kg ...........................................................

metal other than steel or aluminum (50N).

Paper

50 kg ..........................................................

flexible plastics (51H).

1

Fiber

50 kg ............................................................

rigid plastics (50H).

natural wood (50C).

plywood (50D).

reconstituted wood (50F).

rigid fiberboard (50G).

1

Flexible plastic (51H) Large Packagings are only authorized for use with flexible inner packagings.

2

Except when authorized under Special Provision 41.

(5)

‘‘N’’ codes.

These provisions apply

only to non-bulk packagings:

Code/Special Provisions

N3

Glass inner packagings are permitted in

combination or composite packagings only

VerDate Sep<11>2014

16:41 Oct 31, 2018

Jkt 244226

PO 00000

Frm 00377

Fmt 8010

Sfmt 8010

Q:\49\49V2.TXT

PC31