181

Federal Aviation Administration, DOT

Pt. 23, SFAR No. 23

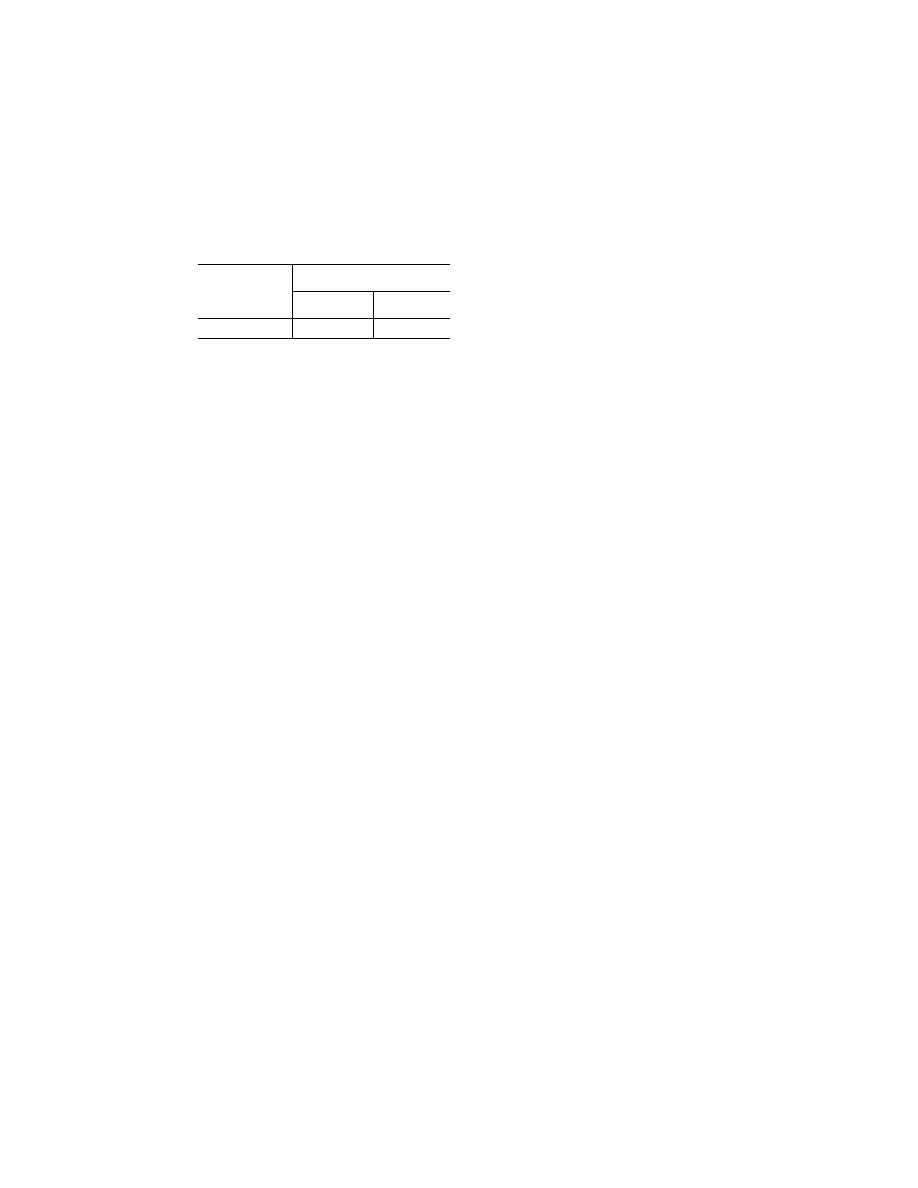

Total seating capacity

Minimum main passenger aisle

width

Less than 25

inches from floor

25 inches and

more from floor

10 through 23 ...........

9 inches .............

15 inches.

M

ISCELLANEOUS

33.

Lightning strike protection. Parts that

are electrically insulated from the basic air-

frame must be connected to it through light-

ning arrestors unless a lightning strike on

the insulated part—

(a) Is improbable because of shielding by

other parts; or

(b) Is not hazardous.

34.

Ice protection. If certification with ice

protection provisions is desired, compliance

with the following requirements must be

shown:

(a) The recommended procedures for the

use of the ice protection equipment must be

set forth in the Airplane Flight Manual.

(b) An analysis must be performed to es-

tablish, on the basis of the airplane’s oper-

ational needs, the adequacy of the ice protec-

tion system for the various components of

the airplane. In addition, tests of the ice pro-

tection system must be conducted to dem-

onstrate that the airplane is capable of oper-

ating safely in continuous maximum and

intermittent maximum icing conditions as

described in FAR 25, appendix C.

(c) Compliance with all or portions of this

section may be accomplished by reference,

where applicable because of similarity of the

designs, to analysis and tests performed by

the applicant for a type certificated model.

35.

Maintenance information. The applicant

must make available to the owner at the

time of delivery of the airplane the informa-

tion he considers essential for the proper

maintenance of the airplane. That informa-

tion must include the following:

(a) Description of systems, including elec-

trical, hydraulic, and fuel controls.

(b) Lubrication instructions setting forth

the frequency and the lubricants and fluids

which are to be used in the various systems.

(c) Pressures and electrical loads applica-

ble to the various systems.

(d) Tolerances and adjustments necessary

for proper functioning.

(e) Methods of leveling, raising, and tow-

ing.

(f) Methods of balancing control surfaces.

(g) Identification of primary and secondary

structures.

(h) Frequency and extent of inspections

necessary to the proper operation of the air-

plane.

(i) Special repair methods applicable to the

airplane.

(j) Special inspection techniques, including

those that require X-ray, ultrasonic, and

magnetic particle inspection.

(k) List of special tools.

P

ROPULSION

GENERAL

36.

Vibration characteristics. For turbo-

propeller powered airplanes, the engine in-

stallation must not result in vibration char-

acteristics of the engine exceeding those es-

tablished during the type certification of the

engine.

37.

In-flight restarting of engine. If the en-

gine on turbopropeller powered airplanes

cannot be restarted at the maximum cruise

altitude, a determination must be made of

the altitude below which restarts can be con-

sistently accomplished. Restart information

must be provided in the Airplane Flight

Manual.

38.

Engines—(a) For turbopropeller powered

airplanes. The engine installation must com-

ply with the following requirements:

(1)

Engine isolation. The powerplants must

be arranged and isolated from each other to

allow operation, in at least one configura-

tion, so that the failure or malfunction of

any engine, or of any system that can affect

the engine, will not—

(i) Prevent the continued safe operation of

the remaining engines; or

(ii) Require immediate action by any crew-

member for continued safe operation.

(2)

Control of engine rotation. There must be

a means to individually stop and restart the

rotation of any engine in flight except that

engine rotation need not be stopped if con-

tinued rotation could not jeopardize the safe-

ty of the airplane. Each component of the

stopping and restarting system on the engine

side of the firewall, and that might be ex-

posed to fire, must be at least fire resistant.

If hydraulic propeller feathering systems are

used for this purpose, the feathering lines

must be at least fire resistant under the op-

erating conditions that may be expected to

exist during feathering.

(3)

Engine speed and gas temperature control

devices. The powerplant systems associated

with engine control devices, systems, and in-

strumentation must provide reasonable as-

surance that those engine operating limita-

tions that adversely affect turbine rotor

structural integrity will not be exceeded in

service.

(b)

For reciprocating-engine powered air-

planes. To provide engine isolation, the pow-

erplants must be arranged and isolated from

each other to allow operation, in at least one

configuration, so that the failure or malfunc-

tion of any engine, or of any system that can

affect that engine, will not—

(1) Prevent the continued safe operation of

the remaining engines; or

(2) Require immediate action by any crew-

member for continued safe operation.

39.

Turbopropeller reversing systems. (a) Tur-

bopropeller reversing systems intended for

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00191

Fmt 8010

Sfmt 8002

Y:\SGML\232046.XXX

232046

pmangrum on DSK3VPTVN1PROD with CFR