261

Federal Aviation Administration, DOT

§ 23.841

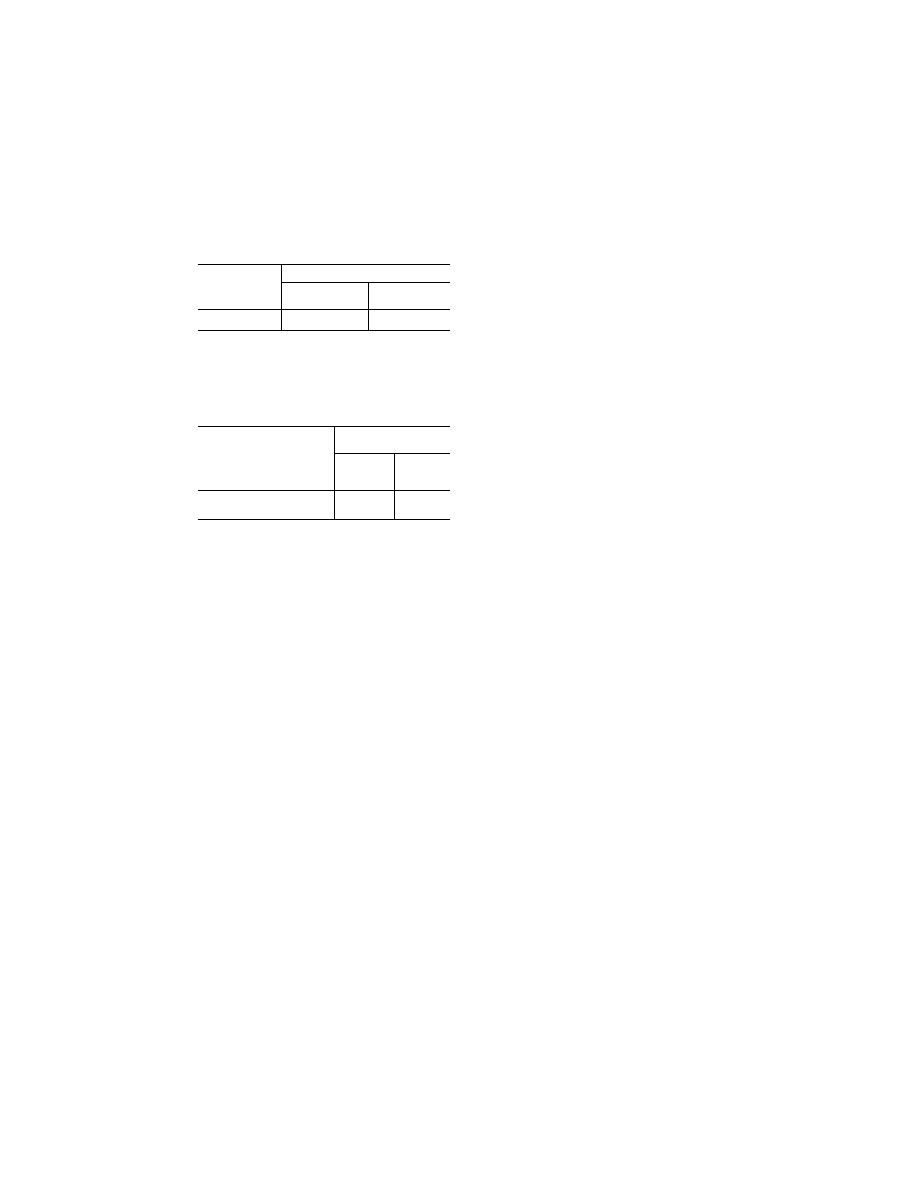

Number of pas-

senger seats

Minimum main passenger aisle width

Less than 25

inches from floor

25 inches and

more from floor

10 through 19 .......

9 inches ................

15 inches.

(b) When certification to the emer-

gency exist provisions of § 23.807(d)(4) is

requested, the main passenger aisle

width at any point between the seats

must equal or exceed the following val-

ues:

Number of passenger seats

Minimum main passenger

aisle width (inches)

Less than

25 inches

from floor

25 inches

and more

from floor

10 or fewer ................................

1

12 15

11 through 19 ............................

12

20

1

A narrower width not less than 9 inches may be approved

when substantiated by tests found necessary by the

Administrator.

[Amdt. 23–34, 52 FR 1831, Jan. 15, 1987, as

amended by Amdt. 23–46, 59 FR 25774, May 17,

1994]

§ 23.831

Ventilation.

(a) Each passenger and crew compart-

ment must be suitably ventilated. Car-

bon monoxide concentration may not

exceed one part in 20,000 parts of air.

(b) For pressurized airplanes, the

ventilating air in the flightcrew and

passenger compartments must be free

of harmful or hazardous concentrations

of gases and vapors in normal oper-

ations and in the event of reasonably

probable failures or malfunctioning of

the ventilating, heating, pressuriza-

tion, or other systems and equipment.

If accumulation of hazardous quan-

tities of smoke in the cockpit area is

reasonably probable, smoke evacuation

must be readily accomplished starting

with full pressurization and without

depressurizing beyond safe limits.

(c) For jet pressurized airplanes that

operate at altitudes above 41,000 feet,

under normal operating conditions and

in the event of any probable failure

conditions of any system which would

adversely affect the ventilating air, the

ventilation system must provide rea-

sonable passenger comfort. The ven-

tilation system must also provide a

sufficient amount of uncontaminated

air to enable the flight crew members

to perform their duties without undue

discomfort or fatigue. For normal oper-

ating conditions, the ventilation sys-

tem must be designed to provide each

occupant with at least 0.55 pounds of

fresh air per minute. In the event of

the loss of one source of fresh air, the

supply of fresh airflow may not be less

than 0.4 pounds per minute for any pe-

riod exceeding five minutes.

(d) For jet pressurized airplanes that

operate at altitudes above 41,000 feet,

other probable and improbable Envi-

ronmental Control System failure con-

ditions that adversely affect the pas-

senger and flight crew compartment

environmental conditions may not af-

fect flight crew performance so as to

result in a hazardous condition, and no

occupant shall sustain permanent

physiological harm.

[Doc. No. 4080, 29 FR 17955, Dec. 18, 1964; 30

FR 258, Jan. 9, 1965, as amended by Amdt. 23–

34, 52 FR 1831, Jan. 15, 1987; Amdt. 23–42, 56

FR 354, Jan. 3, 1991; Amdt. 23–62, 76 FR 75757,

Dec. 2, 2011]

P

RESSURIZATION

§ 23.841

Pressurized cabins.

(a) If certification for operation

above 25,000 feet is requested, the air-

plane must be able to maintain a cabin

pressure altitude of not more than

15,000 feet, in the event of any probable

failure condition in the pressurization

system. During decompression, the

cabin altitude may not exceed 15,000

feet for more than 10 seconds and 25,000

feet for any duration.

(b) Pressurized cabins must have at

least the following valves, controls,

and indicators, for controlling cabin

pressure:

(1) Two pressure relief valves to auto-

matically limit the positive pressure

differential to a predetermined value

at the maximum rate of flow delivered

by the pressure source. The combined

capacity of the relief valves must be

large enough so that the failure of any

one valve would not cause an appre-

ciable rise in the pressure differential.

The pressure differential is positive

when the internal pressure is greater

than the external.

(2) Two reverse pressure differential

relief valves (or their equivalent) to

automatically prevent a negative pres-

sure differential that would damage

the structure. However, one valve is

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00271

Fmt 8010

Sfmt 8010

Y:\SGML\232046.XXX

232046

pmangrum on DSK3VPTVN1PROD with CFR