346

14 CFR Ch. I (1–1–14 Edition)

Pt. 23, App. F

(h)

Burn length. Burn length is the distance

from the original edge to the farthest evi-

dence of damage to the test specimen due to

flame impingement, including areas of par-

tial or complete consumption, charring, or

embrittlement, but not including areas soot-

ed, stained, warped, or discolored, nor areas

where material has shrunk or melted away

from the heat source.

P

ART

II—T

EST

M

ETHOD

T

O

D

ETERMINE THE

F

LAMMABILITY

AND

F

LAME

P

ROPAGATION

C

HARACTERISTICS OF

T

HERMAL

/A

COUSTIC

I

N

-

SULATION

M

ATERIALS

Use this test method to evaluate the flam-

mability and flame propagation characteris-

tics of thermal/acoustic insulation when ex-

posed to both a radiant heat source and a

flame.

(a)

Definitions.

Flame propagation means the furthest dis-

tance of the propagation of visible flame to-

wards the far end of the test specimen, meas-

ured from the midpoint of the ignition

source flame. Measure this distance after

initially applying the ignition source and be-

fore all flame on the test specimen is extin-

guished. The measurement is not a deter-

mination of burn length made after the test.

Radiant heat source means an electric or air

propane panel.

Thermal/acoustic insulation means a mate-

rial or system of materials used to provide

thermal and/or acoustic protection. Exam-

ples include fiberglass or other batting mate-

rial encapsulated by a film covering and

foams.

Zero point means the point of application of

the pilot burner to the test specimen.

(b)

Test apparatus.

(1)

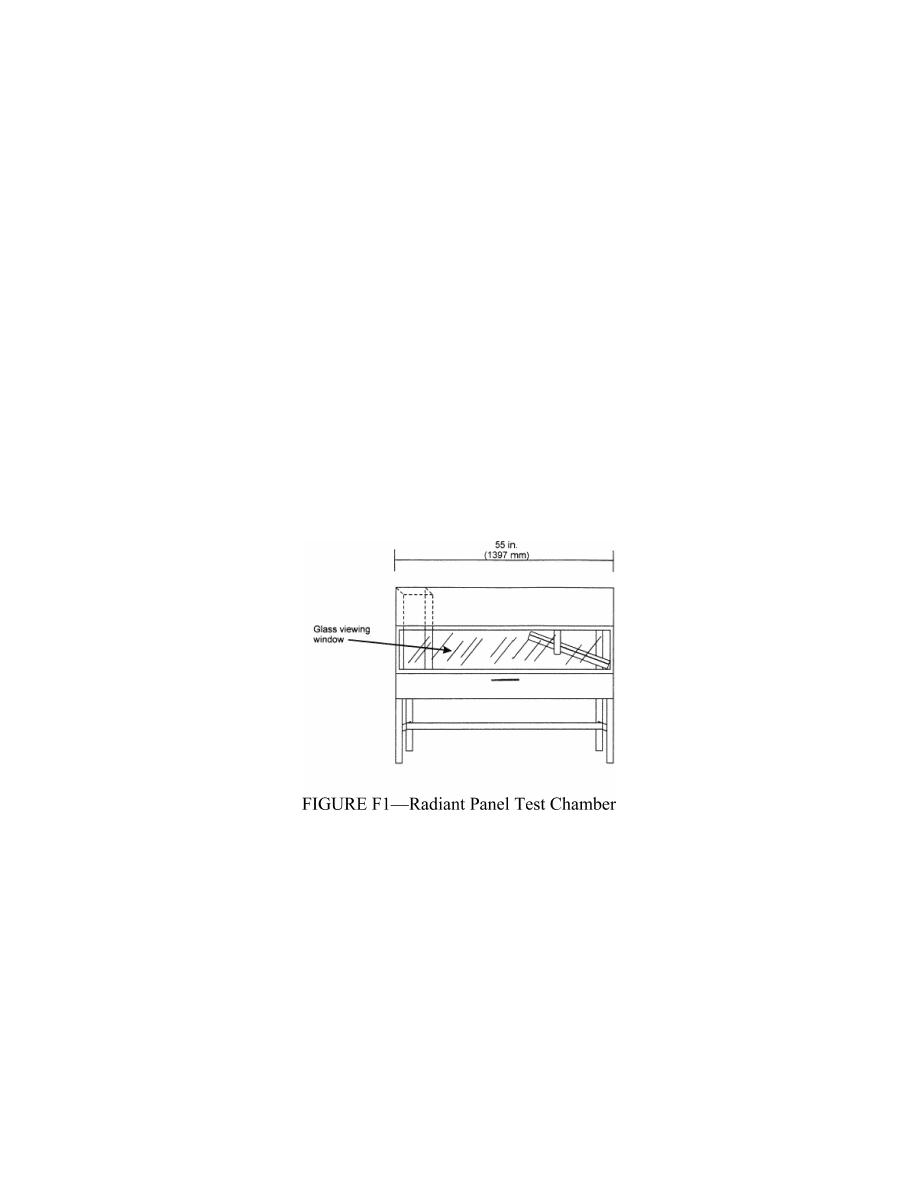

Radiant panel test chamber. Conduct

tests in a radiant panel test chamber (see

figure F1 above). Place the test chamber

under an exhaust hood to facilitate clearing

the chamber of smoke after each test. The

radiant panel test chamber must be an enclo-

sure 55 inches (1397 mm) long by 19.5 inches

(495 mm) deep by 28 inches (710 mm) to 30

inches (maximum) (762 mm) above the test

specimen. Insulate the sides, ends, and top

with a fibrous ceramic insulation, such as

Kaowool MTM board. On the front side, pro-

vide a 52 by 12-inch (1321 by 305 mm) draft-

free, high-temperature, glass window for

viewing the sample during testing. Place a

door below the window to provide access to

the movable specimen platform holder. The

bottom of the test chamber must be a sliding

steel platform that has provision for secur-

ing the test specimen holder in a fixed and

level position. The chamber must have an in-

ternal chimney with exterior dimensions of

5.1 inches (129 mm) wide, by 16.2 inches (411

mm) deep by 13 inches (330 mm) high at the

opposite end of the chamber from the radiant

energy source. The interior dimensions must

be 4.5 inches (114 mm) wide by 15.6 inches (395

mm) deep. The chimney must extend to the

top of the chamber (see figure F2).

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00356

Fmt 8010

Sfmt 8002

Y:\SGML\232046.XXX

232046

ER02DE11.087</GPH>

pmangrum on DSK3VPTVN1PROD with CFR