578

14 CFR Ch. I (1–1–14 Edition)

Pt. 25, App. F

(i)

Electric radiant panel. The radiant panel

must be 3-phase and operate at 208 volts. A

single-phase, 240 volt panel is also accept-

able. Use a solid-state power controller and

microprocessor-based controller to set the

electric panel operating parameters.

(ii)

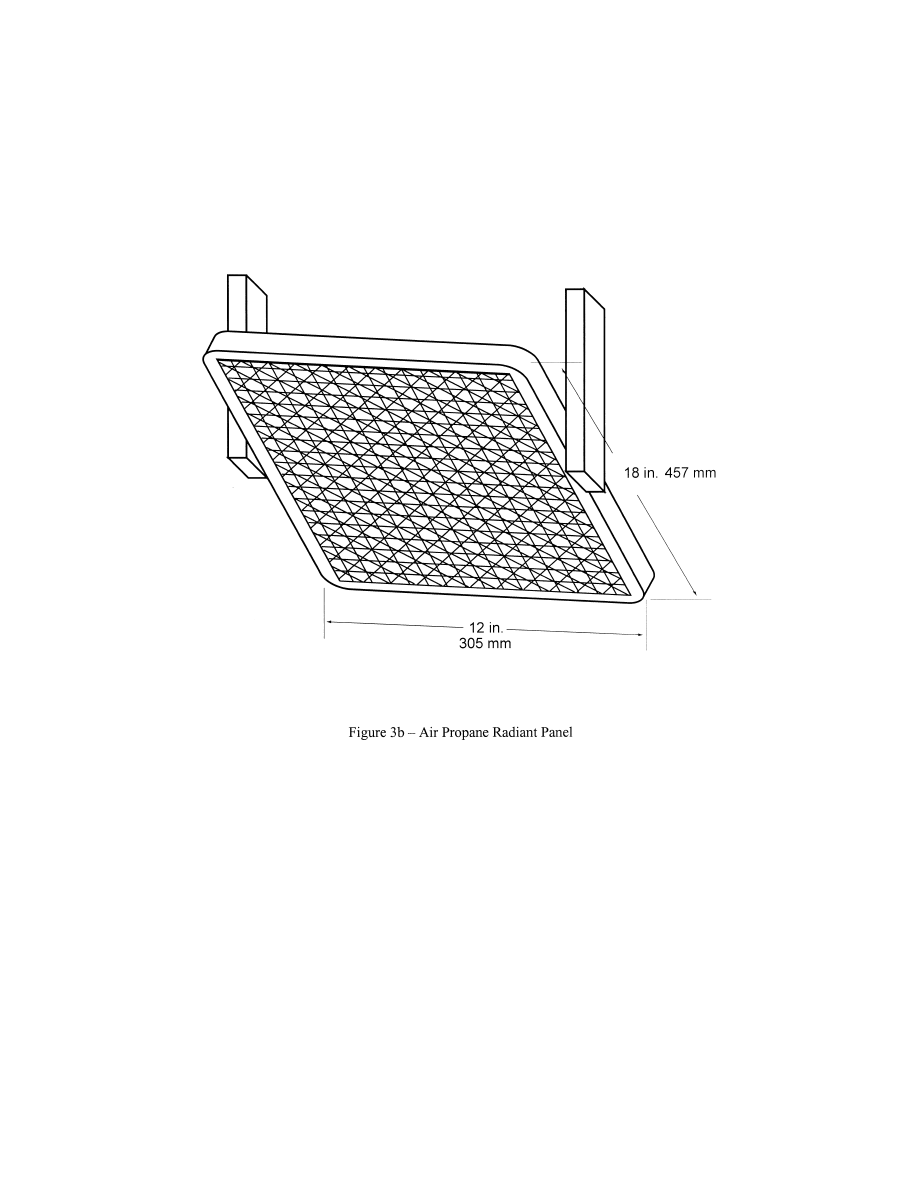

Gas radiant panel. Use propane (liquid

petroleum gas—2.1 UN 1075) for the radiant

panel fuel. The panel fuel system must con-

sist of a venturi-type aspirator for mixing

gas and air at approximately atmospheric

pressure. Provide suitable instrumentation

for monitoring and controlling the flow of

fuel and air to the panel. Include an air flow

gauge, an air flow regulator, and a gas pres-

sure gauge.

(iii)

Radiant panel placement. Mount the

panel in the chamber at 30

°

to the horizontal

specimen plane, and 7

1

⁄

2

inches above the zero

point of the specimen.

(3)

Specimen holding system.

(i) The sliding platform serves as the hous-

ing for test specimen placement. Brackets

may be attached (via wing nuts) to the top

lip of the platform in order to accommodate

various thicknesses of test specimens. Place

the test specimens on a sheet of Kaowool

M

TM

board or 1260 Standard Board (manufac-

tured by Thermal Ceramics and available in

Europe), or equivalent, either resting on the

bottom lip of the sliding platform or on the

base of the brackets. It may be necessary to

use multiple sheets of material based on the

thickness of the test specimen (to meet the

sample height requirement). Typically, these

non-combustible sheets of material are

available in

1

⁄

4

inch (6 mm) thicknesses. See

figure 4. A sliding platform that is deeper

than the 2-inch (50.8mm) platform shown in

figure 4 is also acceptable as long as the sam-

ple height requirement is met.

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00588

Fmt 8010

Sfmt 8002

Y:\SGML\232046.XXX

232046

ER31JY03.006</GPH>

pmangrum on DSK3VPTVN1PROD with CFR