353

Federal Aviation Administration, DOT

Pt. 23, App. F

(3) After steady-state conditions have been

reached, move the calorimeter 2 inches (51

mm) from the ‘‘zero’’ position (first hole) to

position 1 and record the heat flux. Move the

calorimeter to position 2 and record the heat

flux. Allow enough time at each position for

the calorimeter to stabilize. Table 1 depicts

typical calibration values at the three posi-

tions.

T

ABLE

1—C

ALIBRATION

T

ABLE

Position BTU/feet

2

sec Watts/cm

2

‘‘Zero’’ Position ..

1.5

1.7

Position 1 ...........

1.51–1.50–1.49

1.71–1.70–1.69

Position 2 ...........

1.43–1.44

1.62–1.63

(4) Open the bottom door, remove the calo-

rimeter and holder fixture. Use caution as

the fixture is very hot.

(f)

Test Procedure.

(1) Ignite the pilot burner. Ensure that it is

at least 2 inches (51 mm) above the top of the

platform. The burner may not contact the

specimen until the test begins.

(2) Place the test specimen in the sliding

platform holder. Ensure that the test sample

surface is level with the top of the platform.

At ‘‘zero’’ point, the specimen surface must

be 7

1

⁄

2

inches

±

1

⁄

8

inch (191 mm

±

3) below the

radiant panel.

(3) Place the retaining/securing frame over

the test specimen. It may be necessary (due

to compression) to adjust the sample (up or

down) in order to maintain the distance from

the sample to the radiant panel (7

1

⁄

2

inches

±

1

⁄

8

inch (191 mm

±

3) at ‘‘zero’’ position). With

film/fiberglass assemblies, it is critical to

make a slit in the film cover to purge any air

inside. This allows the operator to maintain

the proper test specimen position (level with

the top of the platform) and to allow ventila-

tion of gases during testing. A longitudinal

slit, approximately 2 inches (51mm) in

length, must be centered 3 inches

±

1

⁄

2

inch

(76mm

±

13mm) from the left flange of the se-

curing frame. A utility knife is acceptable

for slitting the film cover.

(4) Immediately push the sliding platform

into the chamber and close the bottom door.

(5) Bring the pilot burner flame into con-

tact with the center of the specimen at the

‘‘zero’’ point and simultaneously start the

timer. The pilot burner must be at a 27 de-

gree angle with the sample and be approxi-

mately

1

⁄

2

inch (12 mm) above the sample.

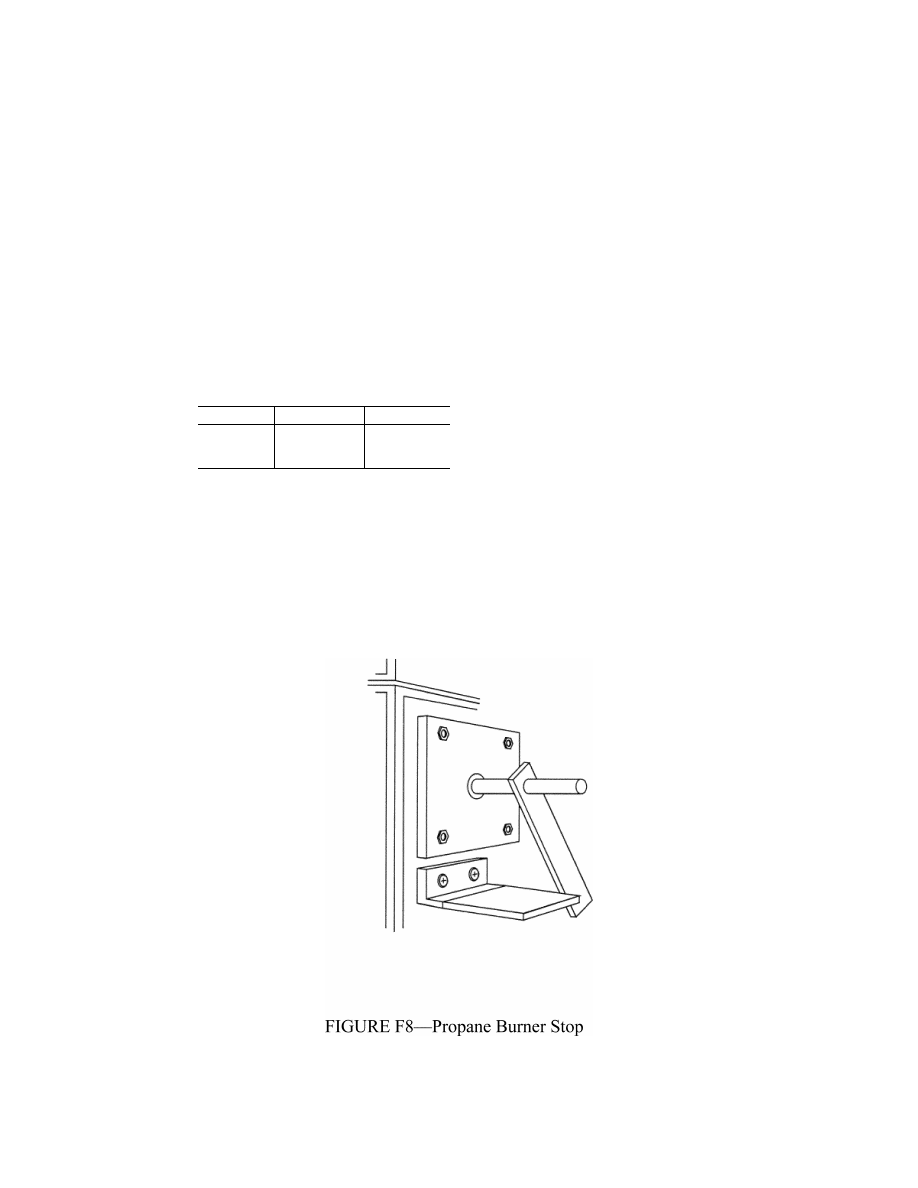

See figure F7. A stop, as shown in figure F8,

allows the operator to position the burner

correctly each time.

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00363

Fmt 8010

Sfmt 8006

Y:\SGML\232046.XXX

232046

ER02DE11.094</GPH>

pmangrum on DSK3VPTVN1PROD with CFR