409

Federal Aviation Administration, DOT

§ 25.415

(2) The minimum forces specified in

§ 25.397(c).

(b) The control system must be de-

signed for pilot forces applied in the

same direction, using individual pilot

forces not less than 0.75 times those ob-

tained under § 25.395.

§ 25.405

Secondary control system.

Secondary controls, such as wheel

brake, spoiler, and tab controls, must

be designed for the maximum forces

that a pilot is likely to apply to those

controls. The following values may be

used:

P

ILOT

C

ONTROL

F

ORCE

L

IMITS

(S

ECONDARY

C

ONTROLS

)

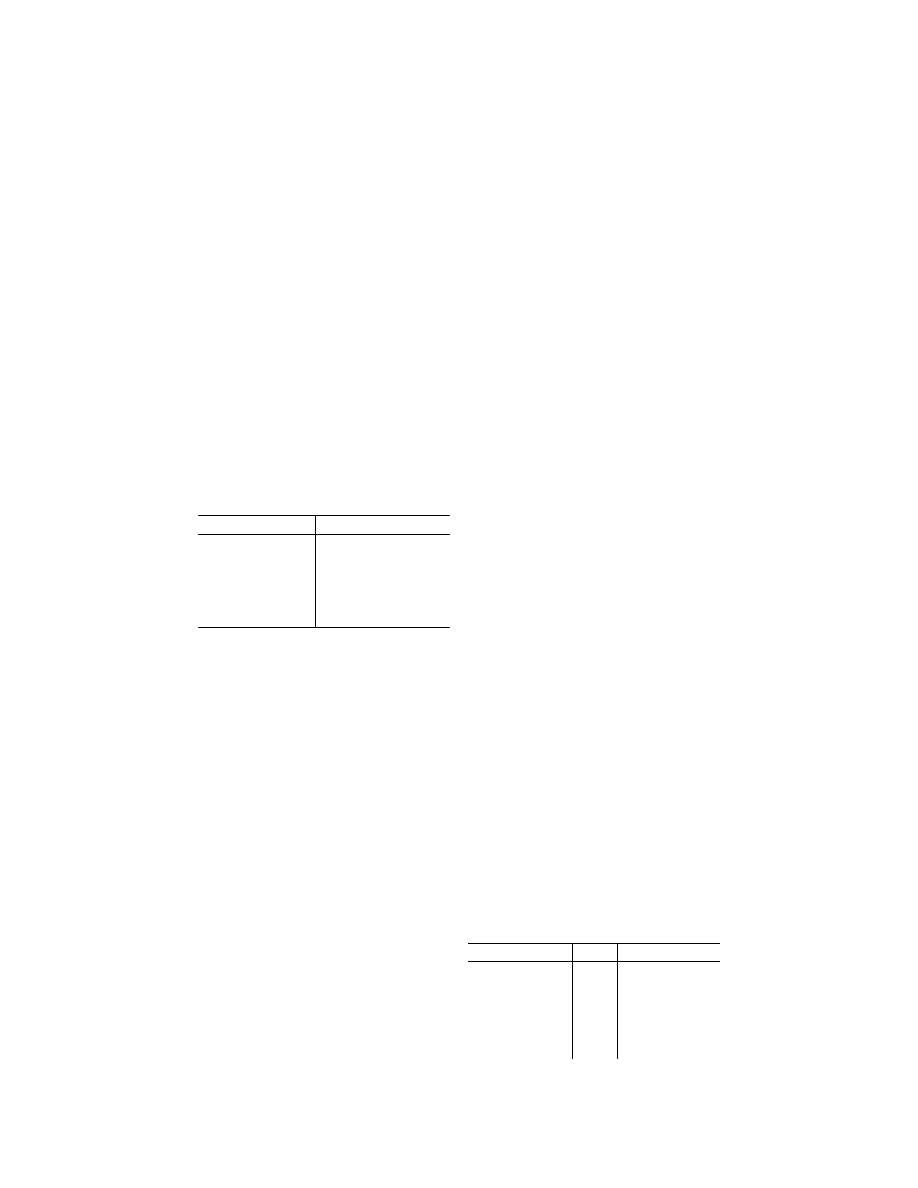

Control

Limit pilot forces

Miscellaneous:

*Crank, wheel, or lever ..

((1 + R) / 3)

×

50 lbs., but not

less than 50 lbs. nor more

than 150 lbs. (R=radius). (Ap-

plicable to any angle within

20

°

of plane of control).

Twist ...............................

133 in.–lbs.

Push-pull ........................

To be chosen by applicant.

*Limited to flap, tab, stabilizer, spoiler, and landing gear op-

eration controls.

§ 25.407

Trim tab effects.

The effects of trim tabs on the con-

trol surface design conditions must be

accounted for only where the surface

loads are limited by maximum pilot ef-

fort. In these cases, the tabs are con-

sidered to be deflected in the direction

that would assist the pilot, and the de-

flections are—

(a) For elevator trim tabs, those re-

quired to trim the airplane at any

point within the positive portion of the

pertinent flight envelope in § 25.333(b),

except as limited by the stops; and

(b) For aileron and rudder trim tabs,

those required to trim the airplane in

the critical unsymmetrical power and

loading conditions, with appropriate

allowance for rigging tolerances.

§ 25.409

Tabs.

(a)

Trim tabs. Trim tabs must be de-

signed to withstand loads arising from

all likely combinations of tab setting,

primary control position, and airplane

speed (obtainable without exceeding

the flight load conditions prescribed

for the airplane as a whole), when the

effect of the tab is opposed by pilot ef-

fort forces up to those specified in

§ 25.397(b).

(b)

Balancing tabs. Balancing tabs

must be designed for deflections con-

sistent with the primary control sur-

face loading conditions.

(c)

Servo tabs. Servo tabs must be de-

signed for deflections consistent with

the primary control surface loading

conditions obtainable within the pilot

maneuvering effort, considering pos-

sible opposition from the trim tabs.

§ 25.415

Ground gust conditions.

(a) The control system must be de-

signed as follows for control surface

loads due to ground gusts and taxiing

downwind:

(1) The control system between the

stops nearest the surfaces and the

cockpit controls must be designed for

loads corresponding to the limit hinge

moments H of paragraph (a)(2) of this

section. These loads need not exceed—

(i) The loads corresponding to the

maximum pilot loads in § 25.397(c) for

each pilot alone; or

(ii) 0.75 times these maximum loads

for each pilot when the pilot forces are

applied in the same direction.

(2) The control system stops nearest

the surfaces, the control system locks,

and the parts of the systems (if any)

between these stops and locks and the

control surface horns, must be designed

for limit hinge moments H, in foot

pounds, obtained from the formula,

H=.0034KV

2

cS, where—

V=65 (wind speed in knots)

K=limit hinge moment factor for ground

gusts derived in paragraph (b) of this sec-

tion.

c=mean chord of the control surface aft of

the hinge line (ft);

S=area of the control surface aft of the hinge

line (sq ft);

(b) The limit hinge moment factor K

for ground gusts must be derived as fol-

lows:

Surface

K

Position of controls

(a) Aileron .....................

0.75 Control column locked

or lashed in mid-posi-

tion.

(b) ......do ......................

1

1

±

0.50

Ailerons at full throw.

(c) Elevator ...................

1

1

±

0.75

(c) Elevator full down.

(d) ......do ......................

1

1

±

0.75

(d) Elevator full up.

VerDate Mar<15>2010

10:12 Mar 18, 2014

Jkt 232046

PO 00000

Frm 00419

Fmt 8010

Sfmt 8010

Y:\SGML\232046.XXX

232046

pmangrum on DSK3VPTVN1PROD with CFR