80

14 CFR Ch. I (1–1–14 Edition)

Pt. 60, App. A

(ii) 55 dB @ 1000 Hz;

(iii) 30 dB @ 16 kHz

(N

OTE

: These limits are for unweighted

1

⁄

3

octave band sound levels. Meeting these lim-

its for background noise does not ensure an

acceptable flight simulator. Airplane sounds

that fall below this limit require careful re-

view and may require lower limits on back-

ground noise.)

(6) Validation testing. Deficiencies in air-

plane recordings should be considered when

applying the specified tolerances to ensure

that the simulation is representative of the

airplane. Examples of typical deficiencies

are:

(a) Variation of data between tail numbers;

(b) Frequency response of microphones;

(c) Repeatability of the measurements.

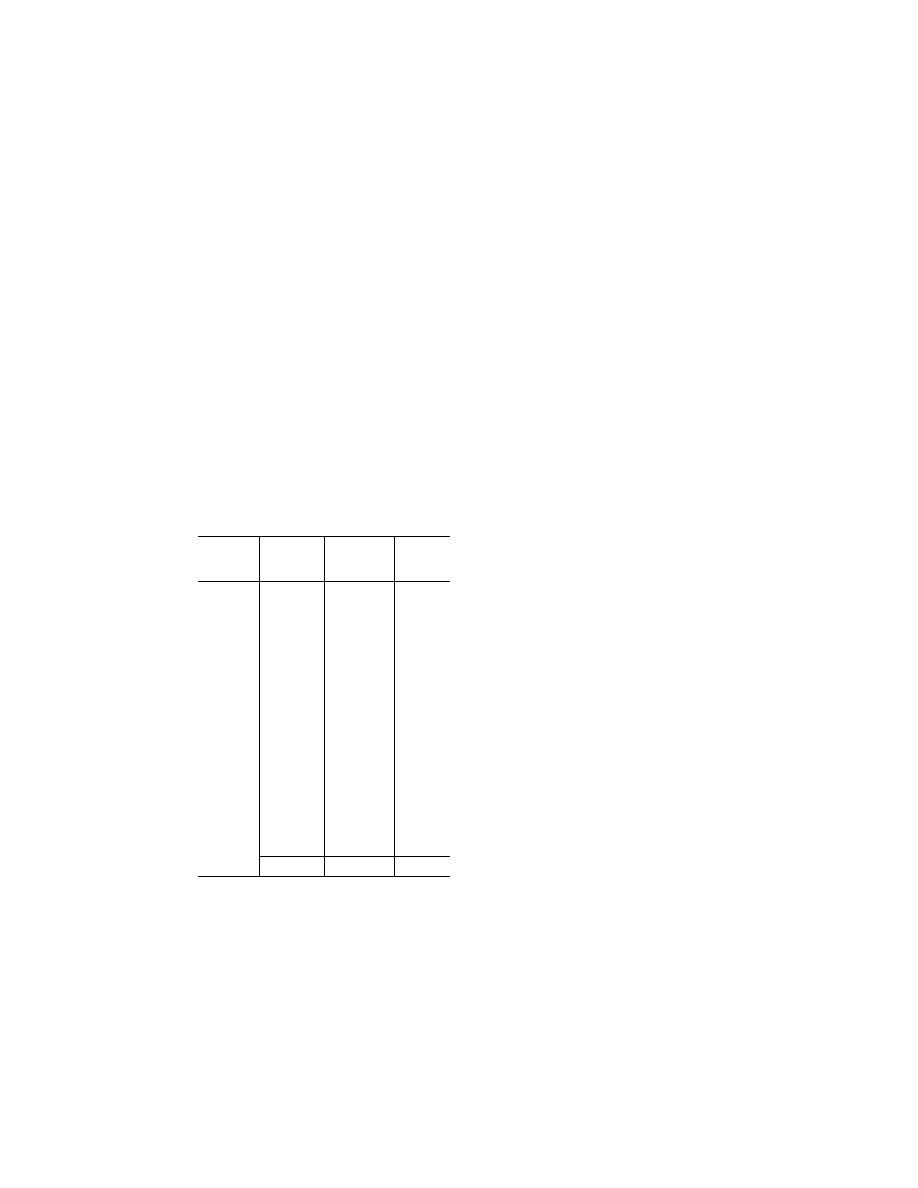

T

ABLE

A2B—E

XAMPLE OF

C

ONTINUING

Q

UALI

-

FICATION

F

REQUENCY

R

ESPONSE

T

EST

T

OL

-

ERANCE

Band center

frequency

Initial results

(dBSPL)

Continuing

qualification

results

(dBSPL)

Absolute

difference

50 .................

75.0 73.8

1.2

63 .................

75.9 75.6

0.3

80 .................

77.1 76.5

0.6

100 ...............

78.0 78.3

0.3

125 ...............

81.9 81.3

0.6

160 ...............

79.8 80.1

0.3

200 ...............

83.1 84.9

1.8

250 ...............

78.6 78.9

0.3

315 ...............

79.5 78.3

1.2

400 ...............

80.1 79.5

0.6

500 ...............

80.7 79.8

0.9

630 ...............

81.9 80.4

1.5

800 ...............

73.2 74.1

0.9

1000 .............

79.2 80.1

0.9

1250 .............

80.7 82.8

2.1

1600 .............

81.6 78.6

3.0

2000 .............

76.2 74.4

1.8

2500 .............

79.5 80.7

1.2

3150 .............

80.1 77.1

3.0

4000 .............

78.9 78.6

0.3

5000 .............

80.1 77.1

3.0

6300 .............

80.7 80.4

0.3

8000 .............

84.3 85.5

1.2

10000 ...........

81.3 79.8

1.5

12500 ...........

80.7 80.1

0.6

16000 ...........

71.1 71.1

0.0

Average ......................

........................

1.1

8. A

DDITIONAL

I

NFORMATION

A

BOUT

F

LIGHT

S

IMULATOR

Q

UALIFICATION FOR

N

EW OR

D

E

-

RIVATIVE

A

IRPLANES

a. Typically, an airplane manufacturer’s

approved final data for performance, han-

dling qualities, systems or avionics is not

available until well after a new or derivative

airplane has entered service. However, flight

crew training and certification often begins

several months prior to the entry of the first

airplane into service. Consequently, it may

be necessary to use preliminary data pro-

vided by the airplane manufacturer for in-

terim qualification of flight simulators.

b. In these cases, the NSPM may accept

certain partially validated preliminary air-

plane and systems data, and early release

(‘‘red label’’) avionics data in order to permit

the necessary program schedule for training,

certification, and service introduction.

c. Simulator sponsors seeking qualifica-

tion based on preliminary data should con-

sult the NSPM to make special arrange-

ments for using preliminary data for flight

simulator qualification. The sponsor should

also consult the airplane and flight simu-

lator manufacturers to develop a data plan

and flight simulator qualification plan.

d. The procedure to be followed to gain

NSPM acceptance of preliminary data will

vary from case to case and between airplane

manufacturers. Each airplane manufactur-

er’s new airplane development and test pro-

gram is designed to suit the needs of the par-

ticular project and may not contain the

same events or sequence of events as another

manufacturer’s program, or even the same

manufacturer’s program for a different air-

plane. Therefore, there cannot be a pre-

scribed invariable procedure for acceptance

of preliminary data, but instead there should

be a statement describing the final sequence

of events, data sources, and validation proce-

dures agreed by the simulator sponsor, the

airplane manufacturer, the flight simulator

manufacturer, and the NSPM.

N

OTE

: A description of airplane manufac-

turer-provided data needed for flight simu-

lator modeling and validation is to be found

in the IATA Document ‘‘Flight Simulator

Design and Performance Data Require-

ments,’’ as amended.

e. The preliminary data should be the man-

ufacturer’s best representation of the air-

plane, with assurance that the final data will

not significantly deviate from the prelimi-

nary estimates. Data derived from these pre-

dictive or preliminary techniques should be

validated against available sources includ-

ing, at least, the following:

(1) Manufacturer’s engineering report. The

report should explain the predictive method

used and illustrate past success of the meth-

od on similar projects. For example, the

manufacturer could show the application of

the method to an earlier airplane model or

predict the characteristics of an earlier

model and compare the results to final data

for that model.

(2) Early flight test results. This data is

often derived from airplane certification

tests, and should be used to maximum ad-

vantage for early flight simulator valida-

tion. Certain critical tests that would nor-

mally be done early in the airplane certifi-

cation program should be included to vali-

date essential pilot training and certifi-

cation maneuvers. These include cases where

a pilot is expected to cope with an airplane

failure mode or an engine failure. Flight test

VerDate Mar<15>2010

20:48 Jan 30, 2014

Jkt 232047

PO 00000

Frm 00090

Fmt 8010

Sfmt 8002

Q:\14\14V2.TXT

ofr150

PsN: PC150